Screen Printing Supply

From Cleaning Supplies to Spare Screens We Have Everything You Need for Your Screen Printing Business!

Prisma PU Heat Transfer Vinyl Product Sheet Vivid and various colors, detailed cutting, effortless weeding, and excellent washing resistance are th...

View full details

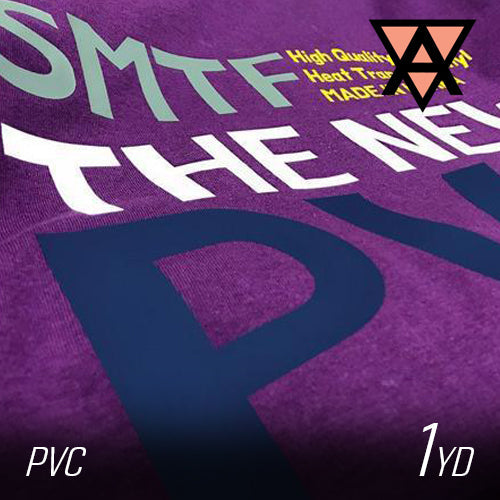

Prisma PVC Warm Peel Heat Transfer Vinyl Product Sheet PVC is a little thicker and high temperature resistant adhesive base PVC vinyl that can hold...

View full details

Prisma Puff PU Heat Transfer Vinyl CPSIA Certificate Prisma Puff PU Heat Transfer Vinyl Product Sheet Puff PU is a polyurethane-based foaming vinyl...

View full details Sale

Sale

Prisma PU Heat Transfer Vinyl Product Sheet Vivid and various colors, detailed cutting, effortless weeding, and excellent washing resistance are th...

View full details

Prisma Glitter Heat Transfer Vinyl Product Sheet Prisma Glitter Heat Transfer Vinyl CPSIA Certificate Very thick PU plotter cut material makes your...

View full details